“Engineering is hard work, and it can be painful to adapt at first.” These thoughts ran through Dr. Gentry Wood’s head before deciding whether or not he should continue to further study after completing his bachelor’s degree. Fast forward to today, he is now the production manager of Apollo-Clad Laser Cladding, a leader in western Canada on the adoption and industrial use of high-powered laser technology for applying weld coatings – and with a PhD to his name.

“My undergraduate and graduate studies did an excellent job of preparing me for the rigours of a career in industrial research and taught me how to think to be able to solve complex problems relying on fundamental engineering principles,” he says.

Dr. Wood owes his success to University of Alberta‘s graduate programmes in Chemical and Materials engineering. In particular, the MEng was designed to prepare industry professionals for leadership roles in today’s competitive job market. The Master of Engineering (Chemical and Materials Engineering), specifically, bridges the gap between academia and industry, ensuring that you are equipped to thrive in any sector, whether in energy or advanced materials.

Housed within the Department of Chemical and Materials Engineering, the programme includes specialisations in Chemical Engineering, Materials Engineering, Process Control, and Welding Engineering. Each is tailored to meet industry demands, particularly in oil and gas, energy, and sustainable resource development – all of which are major driving forces in Alberta. The programme also opens doors to different areas like process engineering, AI-driven industrial systems, and advanced manufacturing – further expanding a graduate’s list of career opportunities.

The Master of Engineering (Chemical and Materials Engineering) includes four specialisations: Chemical Engineering, Materials Engineering, Process Control, and Welding Engineering. Source: University of Alberta

Whichever area you specialise in, this course-based programme emphasises practical learning to enhance your skills so that they translate directly to professional work. “As a production engineering manager, my mission is a unique one: to apply fundamental engineering principles,” Dr. Wood says. “It has been one of the most rewarding experiences of my professional life to see the implementation of my work make a difference to our business.”

For graduate Angelica Vallejo, though, it was her soft skills – something the programme also emphasises in its curriculum – that proved useful to her job. “Currently, I work in the CME department (yes, the same one I studied) as the Experiential Learning and Student Engagement Coordinator,” she says. “My current job requires me to manage several projects in various areas and different stakeholders. This has taught me how to be effective in my duties and responsibilities regardless of the audience the project is targeted to.”

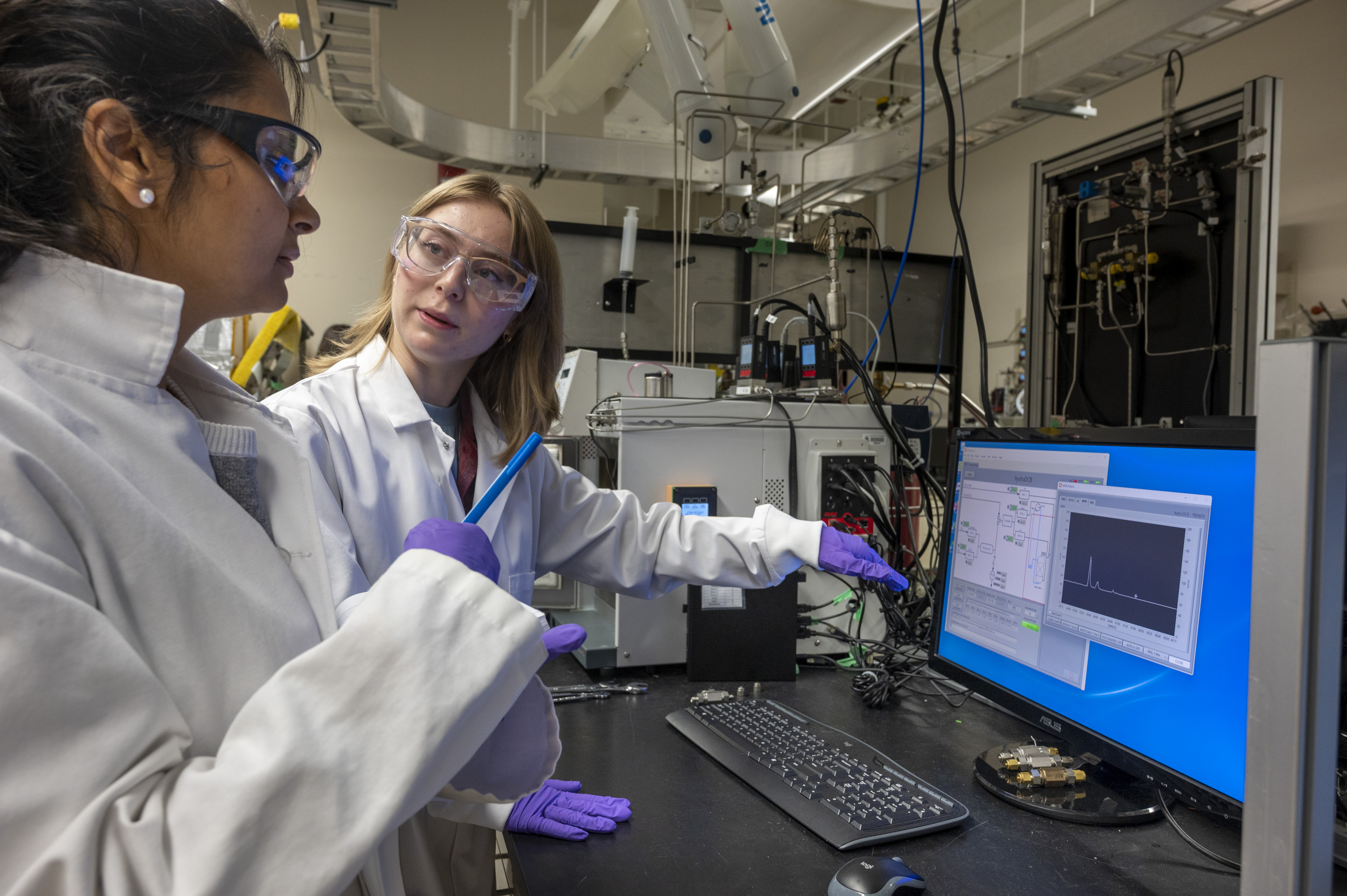

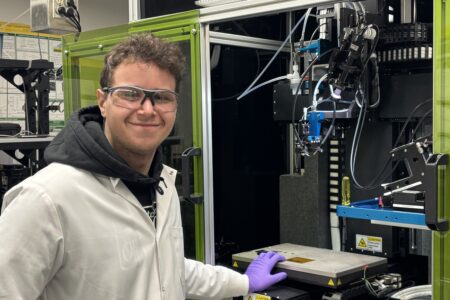

Your learning process does not just end in the classroom. You will also have access to laboratories and facilities equipped with the latest technologies mirroring current industry standards.

Take the Canadian Centre for Welding and Joining (CCWJ), for example. Here, you will assist or even conduct research centring on steel applications and product development, wear protective overlays, numerical modelling of welding, and laser-based advanced manufacturing. Alongside research, the CCWJ has some of the best global connections of any welding centre on the planet, allowing you to build your network prior to getting into the industry.

And with over 350 graduate students and a faculty of 45 experts in the department, collaborations are bound to happen. Whether through group discussions, research projects, or simple Q&A sessions, you will be working with top talents from across the globe.

“During my time as a graduate student, I have worked with professors and researchers from across the globe, and as a student in his lab, I had the opportunity to meet and work with some of the true living legends in welding and materials science,” Dr. Wood says.

By getting involved in the welding technical societies, particularly the Canadian Welding Bureau Association (CWBA) and American Welding Society (AWS), Dr. Wood met other others just as passionate about welding as he was. Today, he serves as the Vice Chair for the Technical Papers Committee of the AWS, where he helps host their annual conference, select scholarship winners for the prestigious AWS Fellowship, and lead their annual poster competition.

“All of these connections and experiences, born from my time in the CCWJ, have shaped my career in ways I could never have anticipated at the onset.”

Students train in labs and facilities equipped with advanced technology. Source: University of Alberta

Once a student of the department, you are automatically part of an extensive alumni network that includes leaders in energy, advanced materials, and sustainability-focused industries. This lets you enhance your connections and reputation in the workforce as the University of Alberta’s MEng degree holders are often recognised for their expertise and professionalism, not to mention the programme itself is ranked among the top in Canada.

Located in Alberta, the heart of Canada’s energy sector, the programme benefits from having close ties with leading oil and gas companies, renewable energy firms, and other industry players. Many students gain direct advantages, just as many find indirect leverage. Dr. Wood belongs in the latter category.

As most of Dr. Wood’s work involves finding new and clever ways to restore expensive, critical equipment used in some of the most aggressive conditions imaginable, he requires the use of aerospace materials or even new materials and strategies for depositing them. The oil and gas sector has made it possible for him to explore more of these exotic solutions. “It has been extremely rewarding to see how solutions for ground engaging equipment developed initially for oil and gas can be applied to other industries with the same challenges such as mining, agriculture, and even naval applications,” he says.

Follow the University of Alberta on Facebook, Instagram, TikTok, X, and YouTube.