An upgraded Apple iPhone is released every two years, but when’s the last time you noticed an improvement to an apple?

Innovation in the world of food can often go unnoticed, but below are examples of game-changing research projects that will potentially revolutionise how we prepare and eat food. They include robotic, biocontrol and chemical solutions to some of our most pressing food issues.

These are all live research projects, developed at The University of Queensland (UQ) in Brisbane, Australia. The UQ scientists involved have been working to improve food technology, known as ‘food-tech’ – a branch of food science that attempts to develop safer and more efficient food production processes.

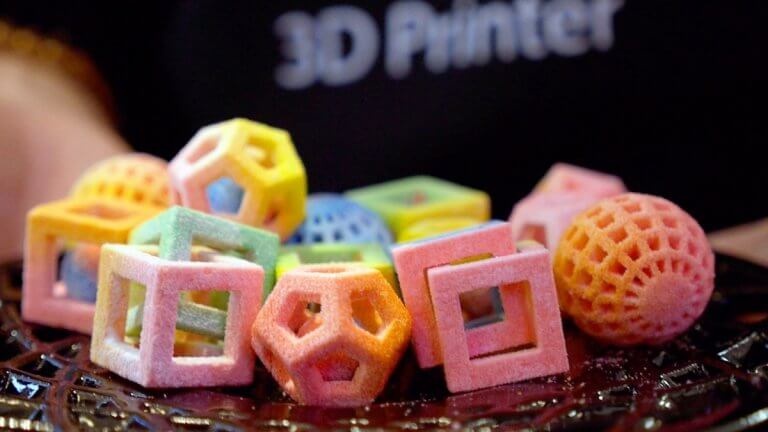

3D Food Printing

The commercially-available Foodini machine lets you 3D print your dinner. (Credit: Foodini)

A team led by Professor Bhesh Bhandari and Dr Sangeeta Prakash are undertaking research on 3D printing of foods, helping develop the next generation of foods that can be made at the simple press of a button.

“There are many potential advantages of 3D printing technology being applied to the food sector, including customised food designs, personalised and digitalised nutrition, the simplification of supply chains, and the ability to broaden the source of food inputs,” says Dr Bhandari.

Beef being printed to into soft mini-burgers. (Credit: Foodini)

“It also allows you to cater for people with both differences in age and ability, such as children, or elderly people with swallowing problems. As an example, we’re able to print a meat pattie that looks just like any other hamburger, but is much easier to swallow, offering a real improvement in quality of life for many people.

“There are so many options. Imagine a world where you can customise not only flavour, but nutritional value, helping give people customised food which match their health needs perfectly. Or you could turn different foods into works of art. You could watch your home appliance create a beautiful sculpture in a matter of seconds. Even our most talented chefs aren’t capable of that.”

“Here at The University of Queensland’s School of Agriculture and Food Sciences, we’re focusing on achieving precise and accurate food printing, while at the same time reviewing the application of 3D printing with food in industry, and investigating trends and challenges faced by 3D food printing.”

Biocontrol of vegetable pathogens

You might not realise it, but your vegetables on the kitchen table could be spawning dangerous bacteria and fungi.

Biocontrols are being used to better protect our vegetables. (Creative Commons)

Rather than resort to potentially harmful chemical controls to better protect us from these pathogens, University of Queensland scientists have been creating biocontrols: the use of organisms to fight pests and disease. Not only do they fight the pathogens, but these biocontrols may also make our food last much longer.

Associate Professor Mark Turner is undertaking research to isolate and identify naturally occurring lactic acid bacteria (LAB) on ready-to-eat vegetables.

“These bacteria are antagonistic toward bacterial pathogens, such as Escherichia coli, Listeria and Salmonella, as well as spoilage fungi,” he explains.

“These LAB are tested as biocontrol agents against pathogens on ready-to-eat vegetables and against spoilage fungi in cheese, with the ultimate aim of improving food safety and making these foods last longer.

“With our high-tech equipment at UQ, we get to use advanced techniques like culture-based antimicrobial screening, Polymerase Chain Reaction (PCR) food testing, DNA sequencing and developed model vegetable growth systems. We now have a collection of over 850 LAB from a variety of different vegetables and fruits in our culture collection.”

Fruit Ripening Powder

We’ve all wanted our fruit to be perfectly ripe on cue, but thanks to the work of some ingenious University of Queensland researchers, we might be able to speed up the process.

Having perfectly ripened fruit may soon be much easier, thanks to University of Queensland research. (Creative Commons)

Fruit ripening is caused by ethylene, a natural gas generated by the fruits themselves. The gas is currently used to control ripen fruit such as bananas, mangoes, avocadoes, citrus and tomatoes.

Professor Bhesh Bhandari and his team of UQ food technologists have created an ethylene powder from food grade material in a safe, easy-to-use format, which can ripen the fruits both in the kitchen, and in large-scale commercial operations. The powder dramatically improves the safety, efficiency and effort involved in controlled ripening of fruit, avoiding the risk of highly flammable gas cylinders causing accidents, as has occurred in the past.

Professor Bhandari says that his new technology is much more flexible in its application, and can help fight inefficiency within the food system, saving time and money.

“The process also allows for very small amounts to be used to ripen small batches of fruit. It could potentially be placed in trucks that transport the fruit from the farm so that the fruit arrives at the market perfectly ripe.

“This powder, along with our other UQ food innovations, will be on dinner tables very soon. This is an exciting place to be – we’re on the cutting-edge of both food and technology.”

For more information about The University of Queensland’s programs and courses, visit the UQ Future Students page.

Follow UQ on Facebook, Twitter, YouTube, Flickr, Instagram and LinkedIn

CRICOS Provider Code: 00025B

Liked this? Then you’ll love…

Plan your research in an idyllic island setting at UQ

Space-age crop breeding innovation at The University of Queensland