The global landscape of engineering is on the brink of unprecedented growth and innovation. As the world hurtles toward an era defined by technological advancements, the demand for adept engineers continues to surge — with an estimated need for an additional 1.8 million engineers in the UK by 2025.

Enter Coventry University. With its state-of-the-art facilities, outstanding student experience, global exposure and industry connections, Coventry University has established itself as the ideal destination to develop students into skilled, industry-ready graduate engineers.

Nestled in the third-best student city in England, Coventry University is home to the School of Mechanical Engineering. Wendy Garner, a Chartered Manufacturing Engineer with 40 years of experience who heads the school, is confident in its approach to assist the next generation of engineers in solving problems that may not currently exist.

“We provide students with foundation knowledge, transferable skills and confidence to enable them to continue to develop and research the field of engineering to ensure that they are up to date during their career,” Garner says.

Garner believes that with emerging technologies like Additive Manufacturing and the shift towards Industry 4.0, including virtual engineering, digital prototyping, and additive manufacturing, product development cycles will become more agile and responsive. This shift will result in stronger products due to extensive computer-aided simulations and digital testing in the virtual world. “The engineer of the future will be working in a fast-paced world, where product development and product launch will be facilitated in a virtual world, informed by a data-rich environment with no global boundaries,” she says.

To prepare students for what’s ahead, the school offers two transformative programmes: Mechanical Engineering MEng/BEng (Hons) and Manufacturing Engineering MEng/BEng (Hons) with foundation year. Both programmes are professionally accredited, providing students with the perfect stepping stone to becoming a Chartered Engineer (CEng).

Mechanical Engineering MEng/BEng (Hons)

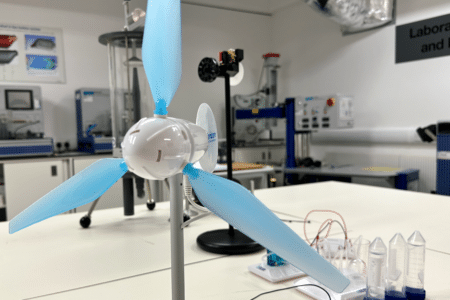

Accredited by the Institute of Mechanical Engineers (IMechE), the Mechanical Engineering MEng/BEng (Hons) equips students with the core and emerging engineering knowledge required by industry. The programme offers a flexible curriculum and hands-on learning, covering fundamental principles and advanced applications in mechanical engineering. Students can choose from diverse modules like biomechanics and advanced manufacturing, tailoring their studies to specific interests, including specialised pathways in renewable energy and propulsion systems.

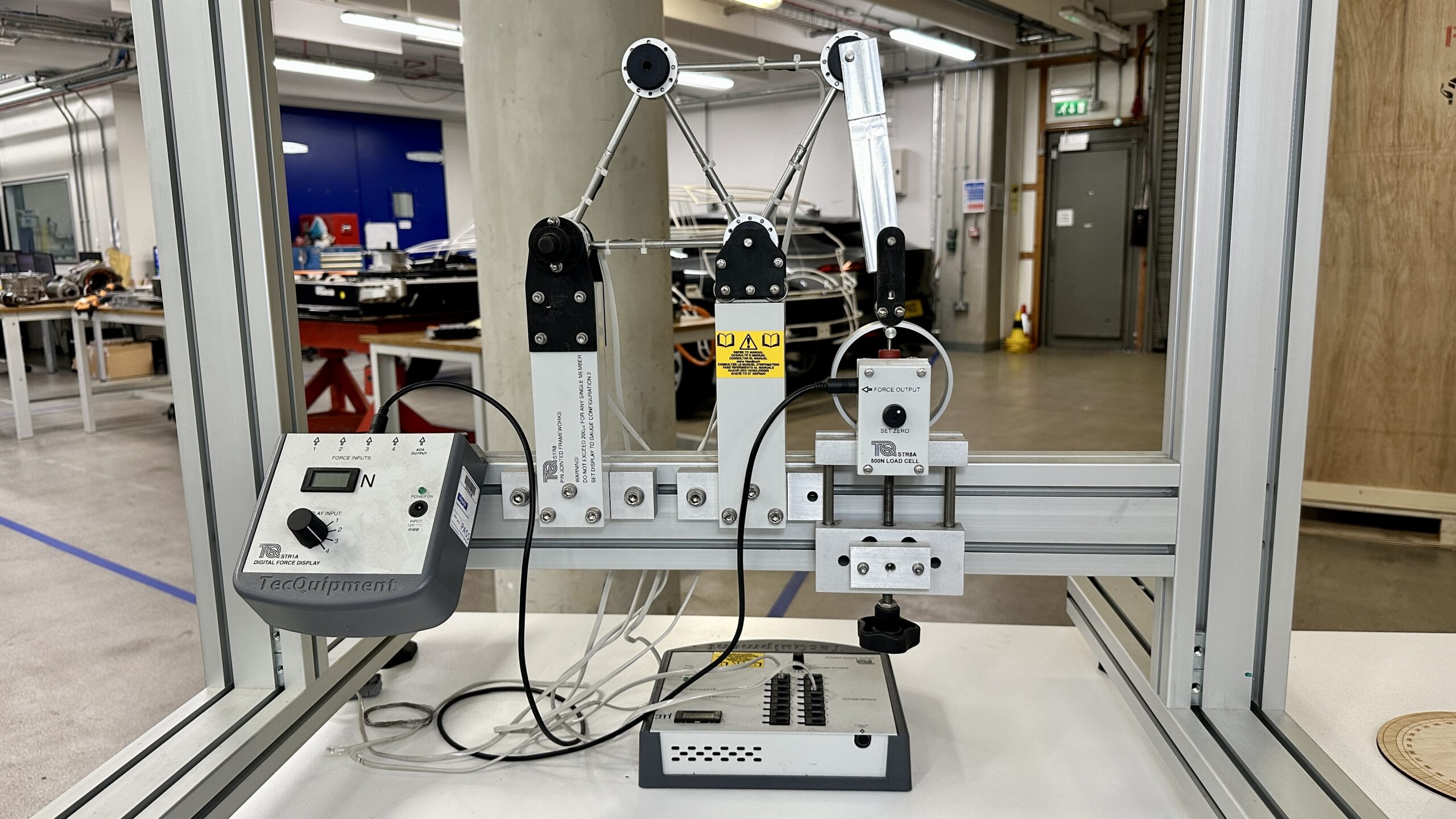

Pair that with industry-standard software, lab, and manufacturing equipment, and students will have the opportunity to gain valuable hands-on experience to contribute effectively in the workplace from day one. Take the IMechE design challenge in year one, for example. Students work in groups to solve a problem using mechanical science, materials, design principles and electrical science — these enable them to acquire real-industry experience and practical employability skills. Past projects include an internal pipe-climber (2018), a repeatable vehicle (2021), a line launcher (2022), and more.

Students also delve into the latest advancements in renewable energy, including improvements in solar cells, wind turbine design, energy storage, and smart grid technologies. Hands-on engineering projects enable students to implement cutting-edge solutions to current challenges in renewable energy technology. For example, the Digital Twin Technologies, material science emphasising lightweight and durable materials, project management focusing on data analytics for “smart” grid technologies, and sustainability assessments provide students with a well-rounded educational experience.

Manufacturing Engineering MEng/BEng (Hons) with foundation year

Accredited by the Institute of Engineering and Technology (IET), the Manufacturing Engineering MEng/BEng (Hons) with a foundation year is designed to produce industry-ready graduates. Each semester, students complete three modules, two of which are taught, while the third is a project-based course. In this module, students tackle real industry problems, employing their academic knowledge to find practical solutions. It’s learning by doing, ensuring that what’s taught in class isn’t just theory but directly applicable in the real world.

Throughout the programme, students work alongside top engineering professionals in the UK, gaining exposure to cutting-edge manufacturing methodologies, particularly at the award-winning Institute for Advanced Manufacturing and Engineering (AME) in partnership with Unipart.

As the UK’s first “Faculty on the Factory Floor,” the AME is a Coventry University centre of engineering excellence. Source: Coventry University

Here, students can access leading research within AME and current manufacturing processes within the Unipart production facility. For instance, they gain firsthand experience in a facility producing essential parts for major automotive players like Jaguar Land Rover, Bentley, and Ford. “In addition to this, we are working alongside companies like Williams F1 and Aston Martin to develop the latest manufacturing technologies in battery manufacture for electric vehicles,” Garner says.

These distinguished features have resulted in a 100% employment rate for students upon completing this programme. Hence, it’s little surprise that the programme achieved a 100% Student Satisfaction rating in the National Student Survey (NSS) 2022.

What’s next for the School of Mechanical Engineering?

The merging of the Metaverse and AI will transform engineering, enabling new ways to work and innovate. Garner believes introducing a cyber-physical reality is already impacting manufacturing and mechanical engineering through the application of “digital twins” to reimagine automation and decrease downtime for retooling production lines.

“Personalised AI can advise human engineers on materials selection, analysis, and stress dynamics in a hitherto unrealised manner. This will result in the fusion of human and machine intelligence that carries us into a completely unimaginable future,” Garner says.

To prepare for this future, click here to learn more about the programmes at Coventry University’s School of Mechanical Engineering.

Follow Coventry University on Facebook, Instagram, X, YouTube, LinkedIn