Nanoscale discoveries at the University of Vermont hold promise for unlocking materials of the future

Try bending your iPhone in half. Or roll up your tablet like a scroll. Or wrap a touchscreen TV around a pole. Didn’t work out so well, did it? That’s because the ceramic material used to make many of today’s touchscreens has only two of three needed qualities: it’s conductive, it’s transparent—but it certainly isn’t flexible.

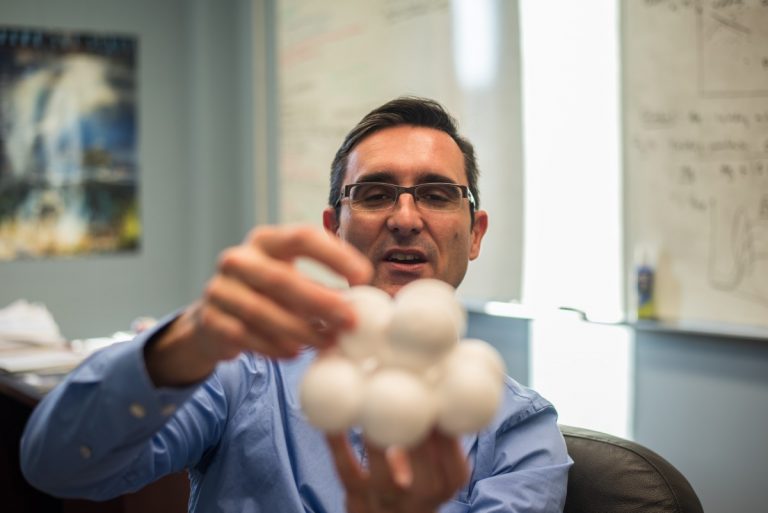

“It’s brittle and so if you bend it, it breaks,” says University of Vermont (UVM) scientist Frederic Sansoz, Professor of Mechanical Engineering.

But Sansoz and his team of scientists have now made a ground-breaking discovery. Working with silver at a vanishingly small scale—nanowires just a few hundred atoms thick—they discovered that they could make wires that were both super strong “and stretchy like gum,” he says.

This kind of silver wire could be fashioned into a mesh that conducts current, allows light to shine through—and bends so easily “you might be able to tie your smartphone into a knot,” he says.

Or, as they write in their study, “we report unusual room-temperature super-elongation without softening in face-centered-cubic silver nanocrystals.”

Small is stronger

UVM’s Sansoz, his collaborator Scott Mao at the University of Pittsburgh, and their colleagues have led pioneering research on how to transform soft metals, including gold, into super-strong wires at the nanoscale. It’s part of a growing area of research that shows that as materials are engineered to become progressively, it’s possible to eliminate many defects at the atomic scale. “And this makes them much stronger,” he says, “generally, smaller is stronger.”

But there’s a problem. “As you make them stronger, they become brittle. It’s chewing gum versus window glass,” Professor Sansoz adds.

Which is why he was very surprised by what the team discovered about silver.

As wires of silver are made smaller and smaller, down to about 40 nanometers, they follow the expected trend: they get relatively stronger and more brittle. But earlier research by other scientists had shown that at even-more-extreme smallness—below 10 nanometers—silver does something weird. “It behaves like a Jello gelatin dessert,” Sansoz say. “It becomes very soft when compressed, has very little strength, and slowly returns to its original shape.”

“So our question was: what’s happening in the gap between 10 nanometers and 40 nanometers?” says Sansoz. “This is the first study to look at the range of diameters in nanowires.”

What the team of scientists found in the gap—using both an electron microscope and atomistic models on a supercomputer—is that “the two mechanisms coexist at the same time,” Sansoz says. This gives silver wires in that little-explored zone both the strength of the “smaller-is-stronger” principle with the liquid-like weirdness of their smaller cousins. At this Goldilocks-like size, when defects form at the surface of the wire as it’s pulled apart, “then diffusion comes in and heals the defect,” Sansoz says. “So it just stretches and stretches and stretches—elongating up to two hundred percent.”

There has been remarkable progress since 2010 in applying silver nanowires in electronics, Sansoz says, including conductive electrodes for touchscreen displays. And some companies are working hard to apply these wires to creating cost-effective flexible screens. “But, right now, they’re manufacturing totally in the dark,” Sansoz says. “They don’t know what size wire is best.” His new discovery should give chemists and industrial engineers a target size for creating silver wires that could lead to the first foldable phones

Severin Schneebeli

The world’s tiniest wrench

In the University of Vermont’s College of Arts and Sciences, chemist Severin Schneebeli has invented a new way to use chirality to create the world’s first nanoscale wrench.

What’s chirality? Hold up your two hands. They are identical in structure, but mirror opposites. No matter how hard you try, they can’t be superimposed onto each other. That’s chirality, from the Greek word for hand. A molecule that is chiral comes in two identical, but opposite, forms—just like a left and right hand.

Schneebeli’s discovery allows scientists to precisely control nanoscale shapes and holds promise as a highly-accurate and fast method of creating customized molecules.

This use of “chirality-assisted synthesis” is a fundamentally new approach to control the shape of large molecules — one of the foundational needs for making a new generation of complex synthetic materials, including polymers and medicines.

Like Legos

Experimenting with anthracene, a substance found in coal, Schneebeli and his team assembled C-shaped strips of molecules that, because of their chirality, are able to join each other in only one direction. “They’re like Legos,” Schneebeli explains. These molecular strips form a rigid structure that’s able to hold rings of other chemicals “in a manner similar to how a five-sided bolt head fits into a pentagonal wrench,” the team writes.

The C-shaped strips can join to each other, with two bonds, in only one geometric orientation. So, unlike many chemical structures — which have the same general formula but are flexible and can twist and rotate into many different possible shapes — “this has only one shape,” Schneebeli says. “It’s like a real wrench,” he says — with an opening a hundred-thousand-times smaller than the width of human hair: 1.7 nanometers.

This wrench, the study shows, can reliably bind to a family of well-known large molecules called “pillarene macrocycles”. These rings of pillarene have often been used as the “host,” in chemistry-speak, to surround and modify other “guest” chemicals in their middle — and they have many possible applications from controlled drug delivery to organic light-emitting substances.

Sir Fraser Stoddart, a world-leading chemist who won a Nobel Prize in 2016, described the study as, “Brilliant and elegant! Creative and simple.”

STEM at the University of Vermont

If you’re passionate about continuing your postgraduate studies in science, technology, engineering and mathematics – the STEM disciplines – it’s an exciting time to join the University of Vermont, where faculty like Sanzos and Schneebeli are expanding our understanding of the world and what’s possible within it. Because of the University’s perfect size and commitment to both teaching and research, you’ll forge a close connection and collaboration with faculty mentors.

You’ll also benefit from the institution’s brand new STEM complex, the largest new facility project in the School’s history, offering cutting-edge teaching and laboratory space. The new complex is right in the center of the historic and beautiful campus, founded in 1791 – a space that makes its home in Burlington, Vermont, perennially named a top U.S. city for its livability, great food, natural surroundings, and rising status as a top technology hub.

Learn more about continuing your studies in the University of Vermont Graduate College.

Follow UVM on Facebook, Twitter, Flickr, YouTube, Instagram and LinkedIn

Liked this? Then you’ll love these…

UVM: Solving the crucial health issues of the modern age

University of Vermont: In Partnership with the World Since 1791