With Industry 4.0 well underway, the fields of biomanufacturing and bioprocessing will be embracing big data and machine learning in new, unexpected areas.

In times of such progress, bioscientists with keen industrial insight and market understanding will have an edge over their research-focused peers.

Why? Well, simply because approaching biomanufacturing and bioprocessing with a business perspective is essential to flourish in their careers.

And while there’s no denying the importance of research, making its findings commercially viable requires a certain set of skills, a business game plan and sharp vision.

As graduates would testify, these are the reasons they chose to study the Master in Biomanufacturing and Bioprocessing (MBB) at the University of Georgia.

“The business side was a big draw for me because I didn’t just want to do pure research — I wanted some business understanding too,” said Janet Fisher from the Class of 2014.

“The MBB courses provided a more holistic perspective on working a scientific position within the industry. I know this would also be incredibly valuable to have if I work in a small company, maybe my own start-up,” she shared.

Fellow graduate Michael Supe agreed that the course was just what he needed to break through into the biomanufacturing industry.

“I was looking for ways to make myself more marketable and learn industrial techniques that would make me employable when I graduated,” he said.

University of Georgia – School of Chemical, Materials and Biomedical Engineering

Rich experiential learning opportunities in biomanufacturing

While many biotechnology programmes merely touch on manufacturing and processing, the MBB programme here takes a slightly different approach.

It focuses on the full biomanufacturing experience, with hands-on training and exposure to industrial-grade equipment.

It combines engineering, science, and business in a multidisciplinary approach to biomanufacturing studies. Another vital component of the MBB is professional training with cutting-edge companies through case-study projects and industry internships.

Together, these components effectively train graduates to become competent leaders in their careers.

Just ask Mark Kasilus, a 2012 alum who joined the University of Georgia to boost his resume and industrial knowledge — and left with a full-time job offer.

Mark joined the programme hoping for a career jumpstart, and that’s what he got when he started an internship with Meredian Bioplastics in Bainbridge, Georgia (now known as Danimer Scientific).

During his internship, Mark supported production plant design through various planning projects. He was then hired as a Process Development Engineer, where he worked on upscaling the company’s polyhydroxyalkanoate (PHA) production.

This endeavour turned into a biopolymer production milestone for the company when Mark and his team created a process to attain desired product purity without harsh solvents.

“An internship is a very low-risk opportunity for an employer to test a high-value employee before they start them out. That’s a huge advantage for those of us who want to immediately get into the workforce,” he explained.

His favourite part of the programme? “Knowing that I was doing something that was directly preparing me for a career,” Mark said.

University of Georgia – School of Chemical, Materials and Biomedical Engineering

The right mix of rigour and support

The MBB is offered under the School of Chemical, Materials and Biomedical Engineering, which is widely recognised as a thought leader in the industrialisation of biology and biological systems.

It is a Professional Science Master’s Degree Programme, which means students are encouraged to pursue advanced STEM training while developing workplace skills.

They are never short on opportunities in this regard thanks to the university’s strong industry ties with companies such as Boehringer Ingleheim, Siemens, Takeda, and Georgia Bio.

At university, students are supported by a multidisciplinary faculty with acclaimed expertise in bio-based manufacturing, renewable energy and chemicals, sustainable new materials and next-gen advanced therapeutics and medical devices.

These lecturers deliver a rigorous, high-quality programme that equips graduates to pursue their interests within the biomanufacturing industry.

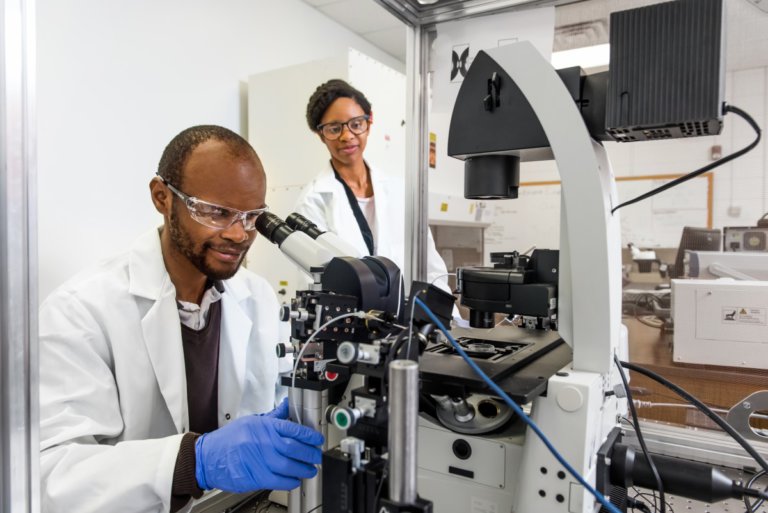

Further supporting experiential learning are the outstanding biomanufacturing facilities at the University of Georgia. Here, students will gain first-hand experience in working with industrial equipment and control systems.

Potential employers and companies that produce biomanufacturing tools will work alongside faculty to guide and challenge students on their postgraduate journey.

As a result, students gain a deep understanding of the scientific and regulatory aspects that underpin fermentation, cell culture and product purification.

More importantly, they will be able to apply that knowledge in a competitive global business community that supports sustainable manufacturing.

Follow the University of Georgia on Facebook, Twitter, Instagram, Snapchat, YouTube and LinkedIn