These are the questions engineers at Michigan Technological University have been asking since the university’s founding in 1885, and the task that graduates from the Materials Science and Engineering (MSE) Department have excelled at since its inception as one of the two founding departments at the Michigan School of Mines in Michigan’s Upper Peninsula.

Back then, the department was known as Metallurgy, and its focus was on ways to extract valuable metals, such as copper or iron, from their naturally occurring states within minerals and underground deposits.

Today, the discipline of Materials Science and Engineering finds ways to use the fundamental physical origins of material behaviour – the science of materials – to optimise properties through structure modification and processing, to design and invent new and better materials, and to understand why some materials unexpectedly fail – the engineering of materials.

Contemporary MSEs work with metals and alloys, ceramics and glasses, polymers and elastomers; electronic, magnetic, and optical materials; composites, and many other emerging materials and processes such as 2-D graphene, nanomaterials and biomaterials, materials that have been 3D printed or additively manufactured, smart materials, and specialised sensors.

Source: Michigan Technological University – Ferrosilicon inoculant is added to a stream of liquid iron. The inoculant provides nucleation sites for creating the proper iron-graphite microstructure in the solidified gray cast iron metal.

Materials Science and Engineering is inherently interdisciplinary – students interact and collaborate with students and scientists in other engineering and science disciplines, such as chemistry and physics.

Despite its legacy and historical central importance to all engineering endeavours, the materials discipline is relatively small compared to other engineering disciplines such as mechanical, electrical, civil, and chemical engineering. In fact, many universities do not have stand-alone materials departments.

“But this is one of the best aspects of being an MSE,” says Michigan Tech MSE Department Chair Steve Kampe.

“Class sizes are small, and students build strong networks with classmates, the faculty and staff, and with like-minded colleagues from other universities from around the world.”

It enables strong learning and collaborative environments with lots of personalised interaction and one-on-one mentoring.

Not only is Kampe a member of the Michigan Tech faculty, he is also an alumnus, earning a Bachelor’s, Master’s and a PhD in Metallurgical Engineering, all from Michigan Tech. He joined academia after working in the corporate research laboratory for a major aerospace company where scientists and engineers developed new products and technologies for the company’s future.

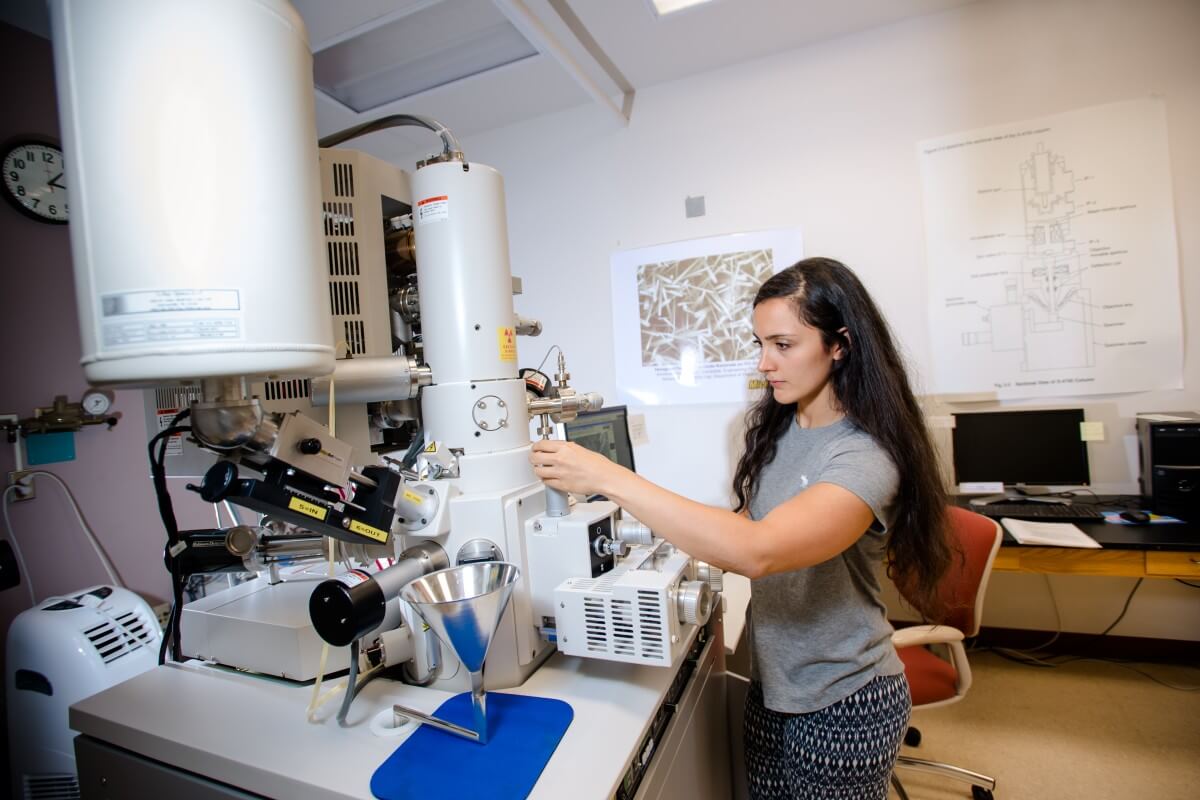

At Michigan Tech, the MSE department manages the university’s suite of scanning electron and transmission electron microscopes, including a unique, high resolution scanning transmission FEI Titan Themis.

The facility also maintains excellent X-ray diffraction, X-ray photoelectron spectroscopy and Auger electron spectroscopy capabilities. In the university’s Institute of Material Processing (IMP), also led by MSE faculty, processing capabilities include melt processing, deformation processing, microelectronic fabrication, and particulate (powder)-based processing capabilities. All students use these world-class facilities, even as undergraduates.

Students at Michigan Tech can join one of 24 Enterprise teams on campus to work on real projects, for real clients. Students invent products, provide services, and pioneer solutions.

Source: Michigan Technological University

Advanced Metalworks Enterprise (AME) is a popular enterprise among MSE students. Small groups within the AME team take ownership of metallurgical manufacturing projects, working closely with industry sponsors.

Being on an Enterprise team helps students build a résumé, develop teamwork skills, form professional relationships, and learn what to expect in the workforce.

“We’re grateful for our corporate sponsors’ help in offering students an opportunity to take textbook skills from the classroom and apply them in practical ways, to experiment, and get results,” says Kampe.

MSE students also get involved in Materials United (MU), a student professional organisation that exposes them to all aspects of Materials Science and Engineering – learning about industry, sharing research, developing personal skills, participating in professional societies and traveling to international conferences.

As one example of student success, MSE students from Michigan Tech won first place in ASM International’s Undergraduate Design Competition the last two years in a row, based on entries from their capstone senior design projects.

Last year, the winning entry was based on a project entitled “Cobalt Reduction in Tribaloy T-400” sponsored by Winsert, Inc of Marinette, Wisconsin.

“Winsert currently uses an alloy similar to Tribaloy T-400, a cobalt-based alloy, in the production of internal combustion engine valve seats,” Kampe explains.

“Cobalt is an expensive element with a rapidly fluctuating price, due to political instability in the supplier countries. The alloy contains approximately 60 wt percent cobalt, contributing significantly to its price. There are also serious sustainability and environmental implications associated with the use of cobalt – both positive and negative,” he says.

“Cobalt is one of the elements used as an anode material for lithium ion batteries that are now under heavy development for electric vehicles.”

Source: Michigan Tecnhological University – A metal matrix composite created by infiltrating magnesium into a carbonized wood lattice.

The student team investigated the replacement of cobalt with other transition elements such as iron, nickel, and aluminum using thermodynamic modelling.

“All MSE senior design projects at Michigan Tech use advanced simulation and modelling tools, experimental callibration, and statistical-based analyses of the results,” adds Kampe.

“The Winsert project utilised software called CALPHAD (Pandat) with machine learning (Bayesian Optimisation) to identify new and promising alloy substitutions. Such advanced techniques are rarely introduced at the undergraduate level in most other MSE programs,” he says.

“Our department’s small size allows meaningful student involvement in leading-edge projects, and close networking with peers, faculty and staff, alumni, and prospective employers,” Kampe says.

The benefits of being a part of a strong professional network continues after graduation.

“Our strong learning community becomes our students’ first professional network after they graduate. It gives them a strong early foundation for a great career,” he said.

Due to the importance of materials to the success of nearly all engineered products, MSEs enjoy employment opportunities in a wide range of industries and in a variety of functions. For example, MSEs are prominent within the automotive, aerospace, electronics, consumer products, and defense industries, performing duties such as new material design, material substitution and optimisation, manufacturing science, and material forensics, such as material identification and failure analyses.

“There are also rich opportunities in corporate and government research and development, since new products and functionalities often start with advancements in our understanding of materials, or in our ability to process them,” says Kampe.

“MSE graduates from Michigan Tech enjoy nearly 100 percent placement at graduation due not only to the reputation of the department, but also due to the fact that just about all engineering-oriented companies rely on materials for their products.”

Follow the Materials Science and Engineering Department at Michigan Technological University on Facebook, Twitter, YouTube and Flickr.

Liked this? Then you’ll love…

Developing the future generation of robotics engineers

Join the materials science and engineering revolution in Industry 4.0